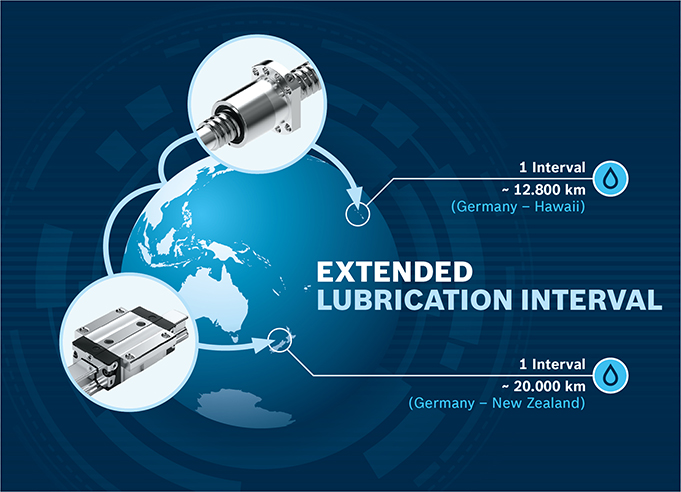

20,000 km without relubrication31.01.2021 11.00

Good news for mechanical engineers and users: the ball rail systems BSHP and ball screw assemblies BASA from Bosch Rexroth now achieve lubrication intervals which are up to four times longer. In more and more applications, they can even be used maintenance-free over the entire service life of a component. As a result, low-maintenance or maintenance-free linear motion technology minimizes operating costs and also protects the environment because less lubricant is required. The results of the most recent tests show that the lubrication intervals for the ball rail systems BSHP are twice as long as they were before. The runner blocks can cover up to 20,000 km before the first relubrication, the same distance as from Germany to New Zealand. The latest generation of ball screw assemblies BASA achieves up to 200 million revolutions with the basic factory lubrication. In this case, the intervals are as much as four times higher. The balls on the screw cover a distance of around 12,800 km – the same distance as from Germany to Hawaii. The fact that the time span until relubrication is now longer for both product groups is due not only to the constant improvements to production processes. Bosch Rexroth’s innovative design plays a role too. Thanks to their patented entry zone, the BSHP runner blocks achieve optimum precision, friction forces and friction force fluctuations. The ball screw assemblies BASA are designed to achieve particularly high load ratings. Both groups of components offer extraordinary robustness, precision and performance. As a result, Bosch Rexroth has put in place ideal conditions for reducing operating costs and protecting the environment. After all, longer lubrication intervals reduce the use of resources. If they double, the quantity of lubricant required is halved. If they are four times as long, only a quarter is needed. For applications which require relubrication, there are various lubrication options to ensure optimum accessibility to the linear guides in the machine. The ball runner blocks BSHP for example are accessible from eight locations. Bosch Rexroth’s linear motion technology is efficient when it comes to engineering too: using the online configurator, a component designed with the Linear Motion Designer program can be configured ready for installation and ordered from the e-shop in a matter of minutes. CAD data are generated and provided automatically. |