Automation and IT in one: Bosch Rexroth training systems make companies fit for Industry 4.007.03.2018 9.00

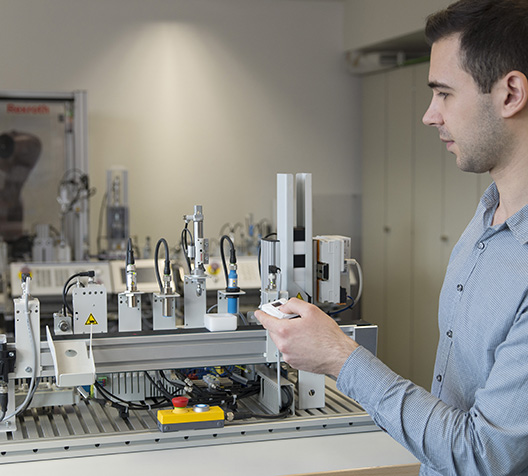

Experts across the world all agree on one thing: Industry 4.0 and the Internet of Things will rapidly change the way work is carried out in factories and production facilities. Training systems for Industry 4.0 from Bosch Rexroth provide a realistic environment for employees to prepare for these new challenges. They are based entirely on open programming and communication standards supported by many different providers worldwide. The new CPS i4.0 training system is designed for production-related work and IT tasks. The hardware and software create a networkable cube assembly system. This allows users to learn forward-looking skills such as programming movement sequences in standard languages, component-led production via RFID and connecting production data with ERP and MES systems. CPS i4.0 is a new addition to the portfolio of training systems for training and developing technical personnel and managers at colleges, universities, and companies. They include hardware, software, and also Teachware, a curriculum comprising didactic tests and the corresponding learning material. Mass-produced microcontrollers are being increasingly used, especially in smaller machines and modules, in addition to conventional PLC automation with hardware developed specifically for mechanical engineering. They can be procured at a low cost and are easy to use as they are programmed using the widespread C-family of standard languages. As a result, personnel with the right training can very quickly network the corresponding automation with IT applications. The new Cyber Physical System CPS i4.0 training system from Bosch Rexroth covers the entire engineering chain, from programming through operation and monitoring to connection to cloud-based services. The training system comprises a workbench with all functional components required for transporting the cubes, identifying their properties, and storing and transmitting this data. It includes an electric conveyor belt, pneumatic actuators, and an extensive range of sensors including an RFID read and write unit. The system’s intelligence comes from the universal XDK microcontroller from Bosch. Functioning as the development platform, the microcontroller includes the hardware and software required for solving real-life tasks. The XDK transmits programming and sensor data to the system via WLAN. The trainees incorporate up to twelve sensors and control up to four actuators. Some of the sensors are accelerometers like the ones used in mobile phones. The IoT gateway from Bosch Rexroth enables all production data to be processed locally and also opens the way for all possible networking options with higher-level systems. All data can be transferred to the internet and shown on a configurable browser interface. |