New component for transfer system TS 2plus: Rexroth introduces the EcoLift EL 230.12.2018 11.01

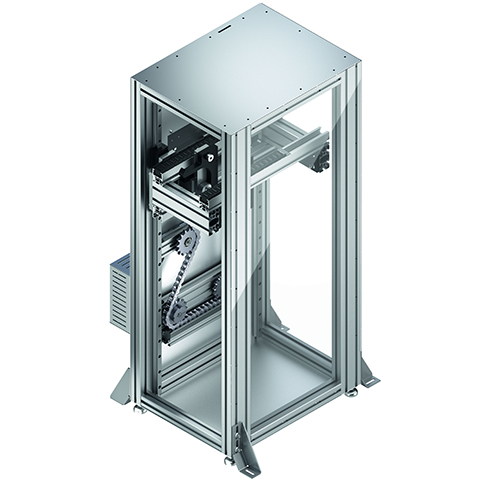

The Rexroth transfer system TS 2plus is the all-rounder in conveyor technology. The standardized modular units and the modular design mean it can be combined in a variety of ways, guaranteeing a broad spectrum of uses. The EcoLift EL 2 will soon offer even more flexibility by expanding the TS 2plus portfolio to include a vertical workpiece transporter module. This makes systems quickly adjustable to individual needs, e.g. for the efficient and space-saving return of empty workpiece pallets – this is possible at a minimum transport height of 290 mm. On the drive side, Rexroth have fitted their own MSM synchronous servo motor, which has impressive integrated safety functions and allows for short time cycles of up to 7.8 s. The new EcoLift EL 2 is the perfect addition for getting the most out of your Rexroth transfer system TS 2plus, even in tight spaces. The lift assumes the workpiece pallet changeover between the two conveying levels at the end of the transfer line – from top to bottom, or vice versa. For example, this allows empty workpiece pallets to be returned below the assembly line so as to implement a space-saving overall layout and to effectively use the space in the assembly hall. The EcoLift EL 2 is particularly economical in this respect as transporting objects horizontally – moving the workpiece pallets in and out of the lift – is done without an additional motor thanks to its simple and sophisticated design. The vertical movement is achieved through the low-wear electric servo motor, MSM, which has an absolute encoder as well as an interface for encoder and power connections. It also reduces the overall energy consumption of the EcoLift EL 2. The electrically activated holding brake integrated into the MSM ensures the necessary safety. The servo motor’s position outside the lift means that maintenance is extremely user-friendly and the servo motor is also easy to replace in case of doubt. The same applies to the easily accessible lubrication unit, which ensures that the oil cartridge can be changed with ease. Servicing is made even simpler by the maintenance hatch and the quick-to-unscrew side plates. Versatile, modular, ready for immediate use The EcoLift EL 2 is suitable for all standard workpiece pallet dimensions up to 800x800 mm and is designed for a weight of up to 60 kg per workpiece pallet. The transport height spectrum ranges from 290 mm to 1,790 mm. Rexroth delivers the EcoLift EL 2 as a fully assembled and constructed unit which can be easily connected to an existing TS 2plus system. The integrated protective enclosure is also included in the standard equipment, made from your choice of opaque iron sheeting or transparent plastic. The lift is low wearing and maintenance friendly thanks to the use of the servo drive and even fewer moving parts, saving costs in the long run. Universal ESD compatibility allows for a safe, protected entire system as well as the option for use in EPA (Electrostatic Protected Area) environments. |