High process reliability at a wide range of variants09.11.2018 11.01

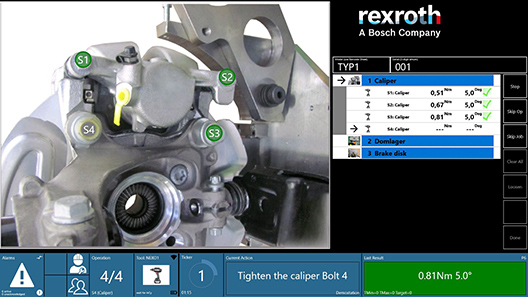

Industry 4.0, diversified production, batch size of 1: the smaller the quantities and the more complex the operation, the more demanding are the requirements for operators in the case of manual, safety-critical tightening operations. The Bosch Rexroth’s Operator Guidance System supports production workers by displaying digitally produced operating instructions on a monitor. This reduces errors and improves process reliability and product quality as part of the assembly process. The PC-based system can be integrated into existing IT structures with minimal hardware and software-related efforts. The virtual guidance system also supports automotive-specific protocols and data output in standard formats. Matching order numbers with production orders, pulling instructions from a folder and fixing them at eye level are all things of the past now, thanks to the Bosch Rexroth’s Operator Guidance System. The system logically arranges and displays the relevant work steps for tightening applications as well as the respective tools required on a monitor. An optional pick-to-light system also identifies the bolts and components required for the job. The visualization prevents rework due to incorrect instructions being used and prevents time lost searching for work instructions. The Operator Guidance System displays every step in the assembly process and provides instructions on how to correct identified errors. Once the assembly work has been completed, it saves all the results and provides full process documentation. The data are then available for end-of-line approval and for full traceability purposes. The virtual guidance system runs on standard PCs running the Windows 10 operating system, optional in conjunction with a touch display. The parameterization of the operational procedures does not require any programming knowledge. The system is also very flexible as users can not only integrate Rexroth nutrunners and spindles but also various different types of tightening-specific hardware such as socket trays and torque wrenches or even employee ID cards and scanners. What’s more, multiple stations can even be configured from one access point. Furthermore, fixed, stationary work stations and work steps in continuous flow production can be interlinked. The Operator Guidance System can be integrated into different planning systems and even complex ERP systems without the need for elaborate interfaces. |