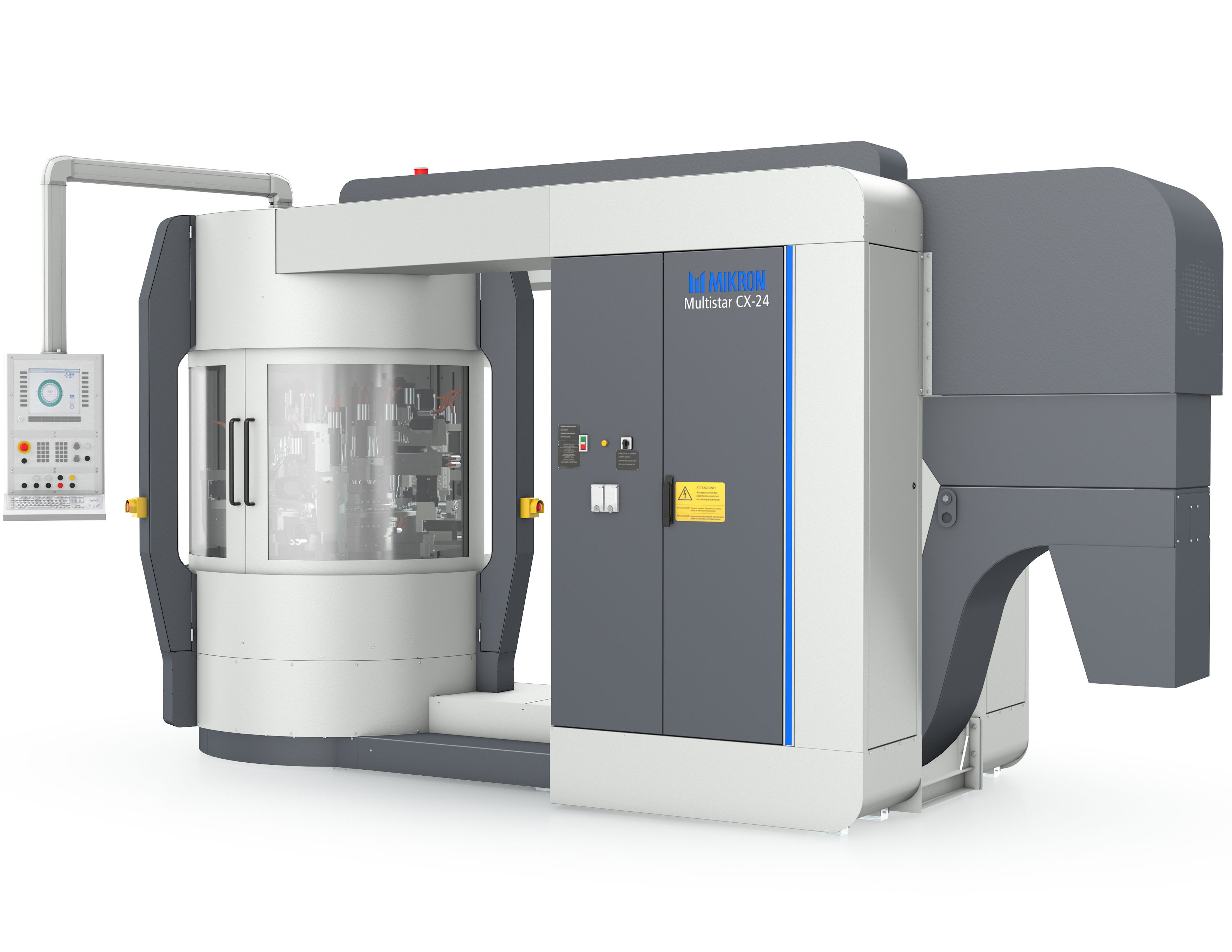

Mikron Multistar CX-24: Flexible for large-scale production30.09.2018 10.11

With the Multistar CX-24, Mikron Machining combines the productivity of a rotary transfer machine with high flexibility for smaller batch sizes. For this, Mikron relies on the open CNC system MTX from Rexroth. The completely redesigned transfer system comprises 24 stations and can be equipped with up to 20 CNC axis. This allows users to quickly and flexibly convert the Multistar CX-24 to different variants within a part family. In large-volume production, rotary transfer machines economically take over the millionfold production of both simple and complex turned and milled parts. In addition to the lowest unit costs in mass production, end users increasingly expect greater flexibility than before in order to respond to ever shorter product lifecycles. In the completely redesigned Multistar CX-24, Mikron is shifting functions that were previously performed mechanically to the software. When redesigning the proven series, they integrated their own technology functions into the open CNC system MTX, protected by know-how. In addition, MTX with Open Core Engineering enables functions programmed in high-level languages to access the control core directly. This is done in parallel to PLC automation according to IEC 61131. In the new rotary transfer machine, Mikron modularly combines 24 stations. When fully expanded, it can simultaneously perform up to 44 machining steps from the top, bottom and sides in a single clamping operation. Mikron uses the CNC system MTX advanced to control all movements. With its multi-core control hardware, it offers sufficient reserves to evaluate extensive measurement data for inline process control without influencing NC block processing. With the integrated OPC UA web server, the transfer system can also be integrated into networked environments. Clear user interfaces fully exploit the technical possibilities of the Multi-Touch operating panel for intuitive operation. Mikron supports the fast changeover with Safe Motion, certified safety functions integrated in the servo drives and frequency inverters of the IndraDrive family. Via a zone module, operators can set all drives of defined stations to Safe Limited Speed (SLS) and Safe Torque Off (STO) safe states at the touch of a finger. Operators and maintenance personnel can safely carry out manual work at the respective station and immediately restart production again without having to switch off the machine completely. Multistar is the only machining system that can be equipped with 48 collets: 24 main collets and 24 additional collets with a different profile enable parts to be turned even with different profiles. Mikron Machining - a division of the Mikron Group - is the leading supplier of customer-specific, high-performance manufacturing systems for the manufacture of complex and high-precision metal components such as turbocharger housings, injection nozzles and ballpoint pen tips. |